BLU IP Management

Intellectual Property Management

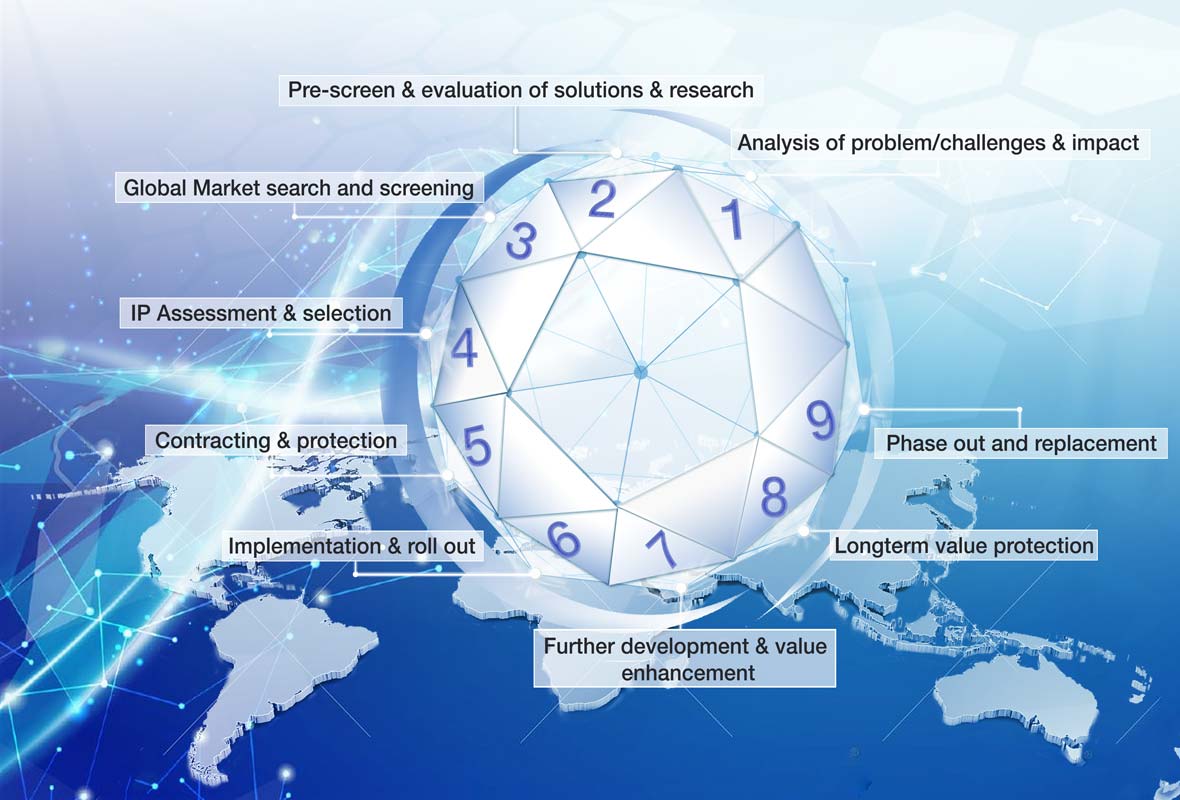

The BLU IP Management approach is a completely new designed process and program management model by BLU that considers years of field experience and state of the art process tools to manage IP in its full lifecycle.

BLU offer to IP owners

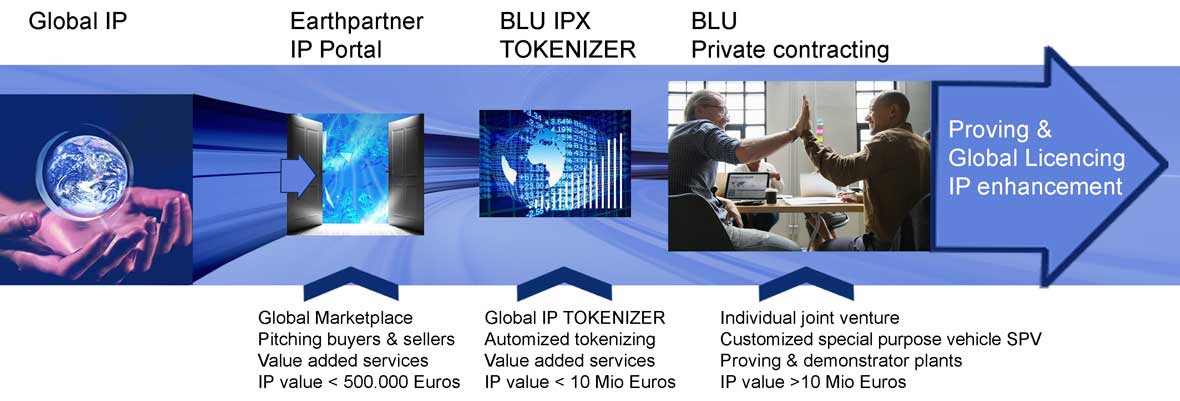

BLU SWARM offers three different business models:

1. Earthpartner.solutions - global IP eXchange & servicing

earthpartner.solutions: World IP Exchange

- internet based matching platform for IP owners and demanders

-

connecting the different parts of the world

-

introducing unproved (simple check) and proved (professional expertise) IP

- promoting IP (promotion platform with strong marketing approach)

-

introducing IP for further development through BLU BRAIN and BLU PCM (private contracting model)

-

integrated part of the BLU platforms and services

2. BLU IPX TOKENIZER – Cash in or cash out – with your IPs

- Platform to trade and tokenize immaterial assets, mainly IPs

- Blockchain based processes (further information: BLU TEC, IPX TOKENIZER)

3.BLU PCM (privat contracting your IPs)

- Selected IPs with blockbuster qualities and an outstanding potential

- Calculated value is managed end to end in a private contracting model

- Long term joint venture, designed individually to the mutual needs and requirements

- IP owner kept in an optimal individual setting on board through all stages

Selection of contracted IPs

Ceramicos

The following summary has to be used as the first information for strategic and financial investors concerning the company CERAMICOS Dental corporation to be established in early 2016. The foundation of CERMAICOS is the patented research and intellectual property of Prof. Dr. Dr. habil. Nikita Hirsch, that will allow CERAMICOS to deliver leading edge products in various industry sectors. These include developments of high innovative materials and production methods that will lead the new company to extraordinary positions in highly profitable market segments. Important USP for each product to be manufactured are secured. The unique manufacturing technologies also allow high margins to be archived for long periods of time.

About

The innovative method developed by the group of Prof. Dr. Dr. habil. Hirsch, based on quantum mechanical effects and the modern nanotechnology, revolutionizes the possibilities for the using of ceramic materials in a bright range of applications. This new development overrides the known limitations of ceramic and other materials. The method – in addition to other immense advantages – gives also the possibility to reduce the energy significantly, required for the compaction and sintering processes by optimally tuned parameters of the innovative technological process flow.

The quantum mechanical manipulation and influencing of ceramic particles during processing gives the possibility to obtain special properties of the ceramic mass, which can be compared with those of molten plastic. This gives, amongst others, also the possibility to obtain a fluid like mass which is suitable for processing in an injection-molding process.

The physical properties of the materials can be adjusted to each use case set of requirements with an innovative tuning method in accordance with defined specifications, such as for example, elastic modulus, toughness, surface compressive strength or tensile strength.

Technology

The method allows significant time savings compared with conventional manufacturing methods. The injection molding techniques as well as other powder pressing methods, through this development, are accessed for previously unthinkable areas. The reason for this is the omitting of the nowadays technical barriers. At this point examples can be mentioned such as applications like ceramic brake discs, shafts, housings, ceramic dental technology and prosthetics, only to name a view.

The newly developed method, implemented in CIM-techniques, gives the possibility to develop wide ranges of entire technical productions, which specially demands for the very complex shapes in combination with specialized surface quality and strength.

Zirconium Dental Blanks are used worldwide for the production of customized dental crowns and dental bridges. The use of blanks allows the dental technician the automated production of such dental restoration parts. The sizes and wanted color to be detected with the aid of a dental scanner

Implants come in use after traumatic injury in the spine. Flexible ceramics can be very quickly accepted by human body and well integrated.

Advantages (some aspects)

The demand for two-part ceramic dental implant increases rapidly, since such implants are the best know alternative to the titanium implants, which brings certain uncontrollable health problems.

One-piece ceramic implants as a completely new development can be very successful based on the business world estimations, in the very fast growing market for dental implants.

In those cases the USPs of Ceramicos process and products come in full play:

-

The calculated manipulation of the ceramic material properties leads to superior features of new products at reasonable cost.

-

Standard products can be made with higher quality and more cost-effective compared to conventional products.

-

Completely new designs and types of products can be designed and produced based on our patented method.

-

New segments of the market can be accessed

Benefits

The method and specially designed materials are also very suitable for the field of medical engineering. Here the requirements for designs and materials are particularly multifarious with the very high demands on the quality structure of the products.

IP

Patents available, some will follow later

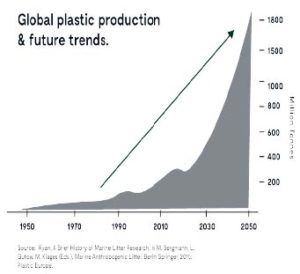

NaturePlastics

|

|

|

|

|

|

|

ALCION aqua SOL

ALCION aqua SOL…

…is a solar driven water station and therefore autarkic

…includes a groundwater drilling with a functioning well

…consists of a solid standard shipping container as center

…contains a filter construction and a UV unit for water preparation

…is cooling the water in a 5000 liter tank

…pumps the water to up to ten points of use

…contains industrial process measuring and control technology that is linked via radio communication to a regional service center

…is protected by a safety fence

«Further IPs»

IPs are constantly searched, contracted and delivered by BLU IP solutions.